Attachment 1 shows the 1-year spot price of nickel and attachment 2 the 1-year LME nickel warehouse stocks level.

Below is a comment from Scotiabank how the nickel price has been rising on potential battery demand for electric vehicles (EV's).

"Is The Nickel Market On Its Way to Becoming Bifurcated? Why Understanding Class I, Class II (and the EV Context) Matters….: In line with the definition provided by the International Nickel Study Group (INSG), refined nickel (class I) includes products such as electrolytic nickel, pellets, briquettes, granulates, rondelles, or powder/flakes with a nickel content of at least 99%. Charge nickel (class II) includes products such as ferro-nickel, nickel oxide, utility nickel, or nickel pig iron (NPI) with a nickel content below 99%. Recall that the difference between the two classes of nickel was recently highlighted by VALE given the company's current frustration in its inability to fully capture the premium for all the class I nickel it produces, because a portion of its higher quality class I output (and class I suitable for batteries) had been being sold to produce stainless steel. Unsurprisingly, VALE is making changes internally to change this and capture more value….

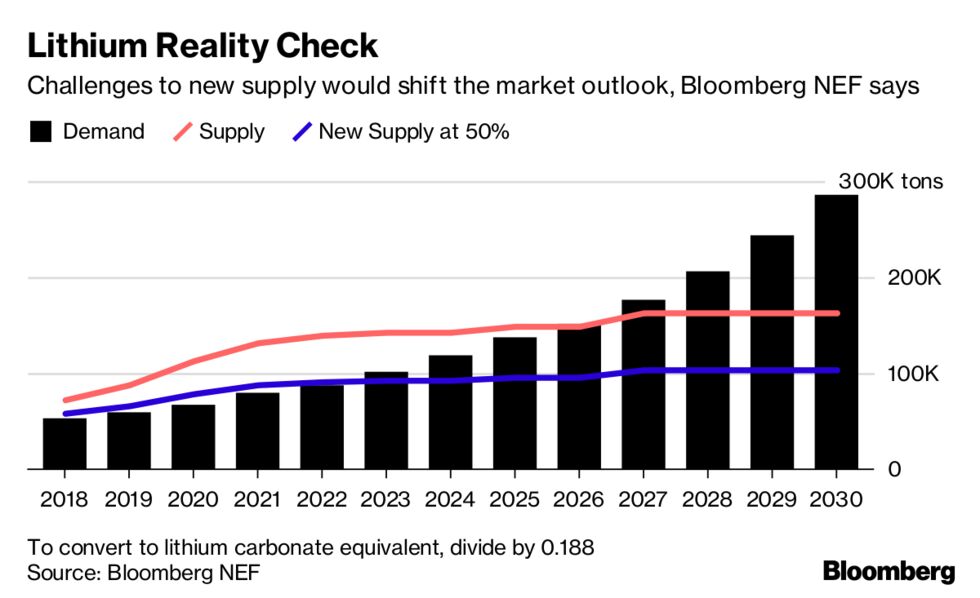

So, Is there a Shortage of (Class I) Nickel for Batteries? Not for a while in Scotia's view. The growing widespread adoption of electric vehicles (EV) in both the Western World and in China has created significant attention and investor interest in several EV inputs including cobalt, nickel, lithium, and copper. While EV demand for nickel currently represents only a minor ~3% of the market, demand is anticipated to materially increase over the next decade. Although growing non-stainless demand is a very positive long-term backdrop for the market, we do not see a looming near-term supply crunch for nickel. Global nickel inventories, while substantially improved (ie. drawn down) from 2016 levels, still remain at historically elevated levels. Looking at visible inventories at a more in-depth level, Scotiabank Senior Base Metals Analyst Orest Wowkodaw notes that there are currently 261,000 tonnes of Class I nickel briquettes sitting in LME warehouses, representing 78% of total LME inventories. Conservatively assuming 100% of the nickel stored in Shanghai and in Chinese bonded warehouses is cathode, briquettes represent ~60% of global nickel inventories. The stainless steel industry consumes primarily nickel cathodes but also nickel briquettes, while the non-stainless sector (including batteries) consumes primarily briquettes. In 2018, Orest forecasts only 31% of nickel demand from the non-stainless sector. While he forecasts this consumption mix to only slightly increase to 35% non-stainless by 2022, he anticipates the size of the overall nickel market to increase by 239,000 tonnes or by 11% during this five-year period. On a more positive note, Orest continue to see a looming shortage for Class I nickel developing next decade as EV demand accelerates during a very long period where prices to develop new greenfield nickel supply remains below incentive levels. In his view, the viable greenfield project pipeline for future Class I nickel supply appears bleak. Furthermore, the appetite to develop another large scale multi-billion dollar HPAL laterite project remains practically non-existent.

While current visible nickel stocks of 355kt (equal to 56 days of consumption) would suggest there is still plenty of available nickel in the market, the rate of YTD inventory decline has been markedly more pronounced than Orest had previously anticipated (he currently forecast year-end 2018 visible stocks of 373kt or 61 days and it's only June). A recent discussion with commodity consultants WoodMackenzie suggest that a large portion of these draw-downs could be attributed to speculative hoarding."